Prototyping, Tooling, and Engineering

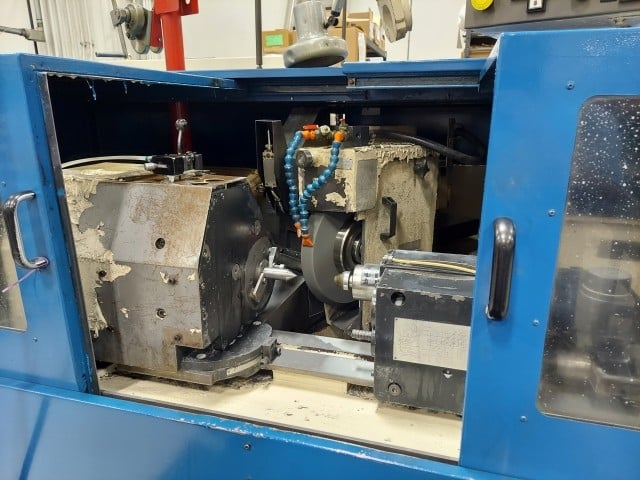

Prototyping & Tooling

At MSI, we do prototyping and tooling in our dedicated, in-house tooling department. If we don't have something essential to a job, we can just make it!

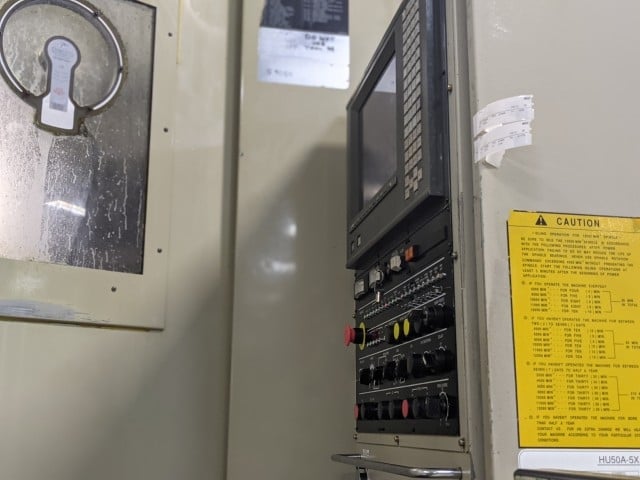

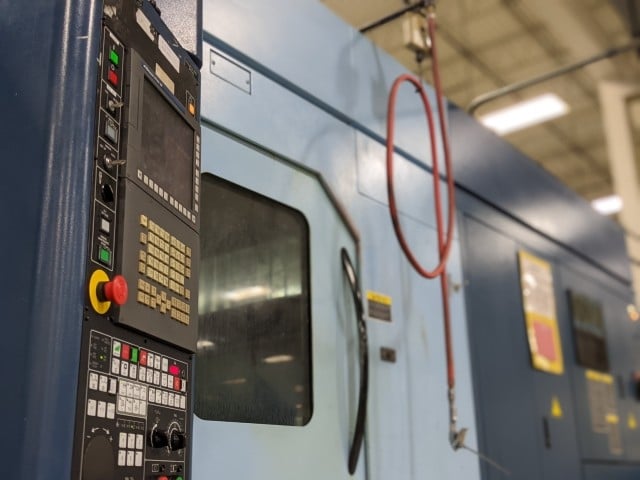

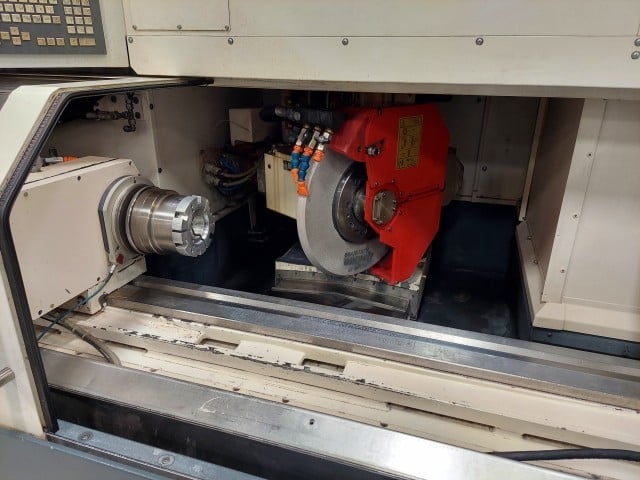

Our tooling capabilities allow us to not only make parts for production, but also make and modify tools. We also make work-holding devices and fixtures for just about anything, including:

- Inspection

- Welding & Fabrication

- EDM

- Grinding

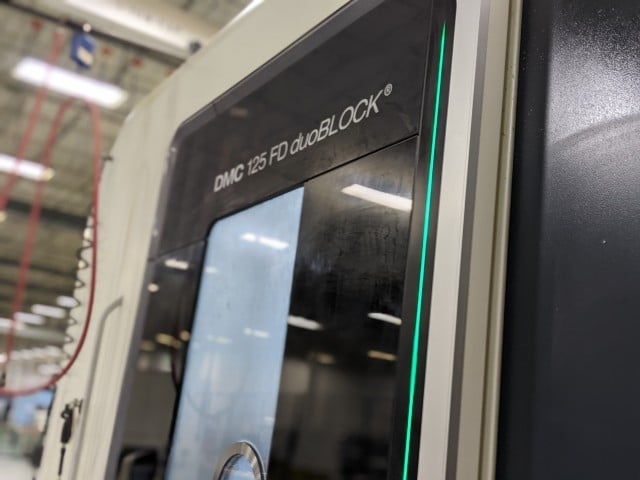

- 3, 4, and 5-Axis Milling

- Mill Turn

- Lathing

Our prototyping abilities also allow us to do short-run jobs without halting the productivity of our other machines, giving us the ability to do R&D on small jobs simultaneously.

Prototyping & Tooling Equipment

hurco vm1

hurco vmx42

hurco vmx42i

hurco vmx50

Engineering & Design

Our engineers use professional-grade CAD/CAM software to generate CNC machine tool programs for the manufacturing process.

Our process is capable of generating machine programs for 3, 4, and 5-axis simultaneous or independent machining on multiple parts with real-time machine tool simulation. We accept a wide variety of file formats, and our CAD/CAM system is electronically interfaced to enable direct loading of programs both to and from our machines!

MSI also uses Epicor, a full-service ERP system designed specifically for manufacturers. Our ERP system provides precise control and documentation of all phases of the manufacturing process. Shop data collection is an integral part of Epicor, and this enables MSI to provide detailed, real-time answers regarding works-in-progress.

Contract Engineering Services

We offer contract engineering services to customers who want to perform in-house machining, but would like the additional expertise or resources that MSI can provide to develop the required processes on their own.

MSI offers any of the following services individually, or you can combine them into a customized, turnkey contract engineering package that meets your specific needs.

- Bills of materials

- Bills of operations

- CNC programs

- Tooling packages

- Work holding fixtures

- Machine tool recommendations

- Machine setup services